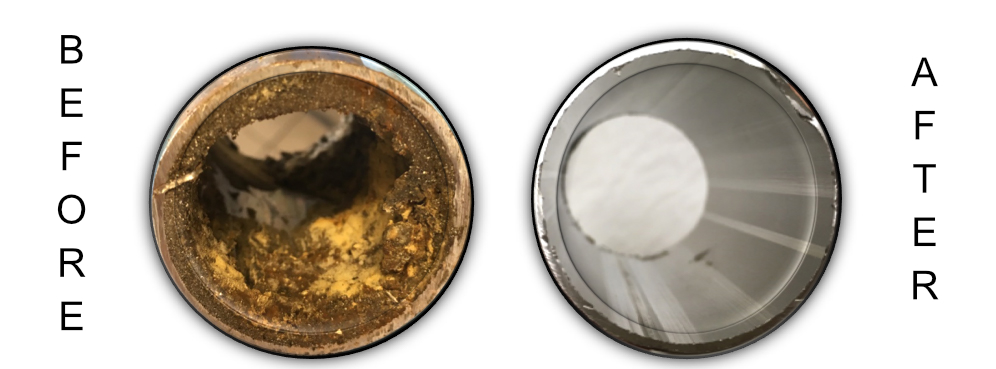

Eliminate tartar with chemical descaling

"Descaling" consists in eliminating all kinds of deposits likely to contaminate or clog a surface. Generally two kinds of tartar are distinguished, mineral tartars and organic tartars.

Present in water networks, industrial and food installations, the phenomenon of scaling requires regular maintenance to ensure the proper functioning of the installations and compliance with hygiene standards.

Scaling of industrial facilities and water networks

Scaling (limescale, mineral scales) occurs when calcium carbonates and to a lesser extent, magnesium carbonates precipitate and form a solid and encrusting "film" on the surface of the pipes.

This phenomenon occurs in networks and capacities that convey or contain hard water. If the water is renewed regularly (open circuit) the scale film will thicken until it obstructs the pipes concerned. In this case, scaling may promote corrosion under deposit. This corrosion leads to the formation of pitting that can cause leaks.

A scale film with an average thickness of 1 millimeter reduces heat exchange (exchangers, boilers, condenser, water heater, etc.) by 25 to 30%. This loss varies according to the homogeneity and compactness of the tartar film, inherent in its deposition rate.

As a result, scale significantly increases the energy consumption of installations and leads to a drop in performance. By reducing the diameter of the pipes, it increases pressure drops and reduces flow rates.

With calcium carbonate, other more or less corrosive components can precipitate the scaling phenomenon: magnesium carbonate, silica and silicates, sulphates, metal oxides and hydroxides, chlorides, microorganisms, etc...

Organic scales are mixed organic and mineral deposits. They are most often deposited and encrusted on the surfaces of installations that process foodstuffs or organic matter (wine industry, food industry, etc.). These organic scales are eliminated thanks to special solutions.

The chemical descaling process

Chemical descaling consists of circulating a chemical agent, generally an acid, in contact with the tartar. The choice of treatment product is very important. It varies according to several parameters such as the nature of the metals that make up the installation, the quantity of scale, its composition, etc...

When possible, Hydrochem offers acids whose calcium salts are very soluble in water (optimization of treatment volume). The composition of the treatment solutions is adapted to the nature of the metals in the installation and inhibited (molecule that protects the healthy metal). Depending on the nature of the solutions used, descaling is carried out at room temperature or hot.

During descaling, the reaction is accompanied by a strong release of gas (CO2) which must be controlled. The progress of the treatment is monitored by chemical analyses.

Descaling is always followed by rinsing and passivation. It is sometimes supplemented by deoxidation when necessary.

Following the dissolution of the scale, the treatment solutions are heavily loaded with minerals/sludge (several grams per litre). A simple neutralization is not enough to allow their rejection. The solutions are collected and then treated in suitable treatment facilities (supply of an Industrial Waste Monitoring Form).

Principle of chemical descaling in an acid environment

The chemical reaction that leads to the elimination of scale deposits is as follows:

CaCO3 + 2H+ to Ca2+ + CO2ä + H2O

The modes of application of the treatment are:

- Immersion

- Filling and circulation

- Sprinkling and runoff

- Spraying

- Application

Descaling monitoring and control

In general, descaling control is visual. It can be done by directly observing the surfaces concerned or by using an endoscope. It is also possible to introduce a control specimen representative of the installation to be treated into the descaling product. Observations are then made directly on this specimen.

Depending on the installations and problems encountered, it is necessary to carry out physico-chemical checks as well as wettability tests. Control of treatment solutions (concentrations of free and total acidity, iron content, hardness, silica, inhibition, etc.) and microbiological controls are also carried out.

Go to a specialized company

The chemical descaling of water networks and industrial installations requires appropriate procedures and the use of specific chemical products.

The intervention of a qualified and specialized professional is strongly recommended. For any request for information, do not hesitate to contact us via the Contact section.